By creating vacuum, any wet solid can be dried or the wetness can be removed. This mass transfer operation in which moisture is present is call vacuum drying. In industries like food, pharmaceutical, agricultural, etc drying is an important operation. This will result in solid finished product. Some functions like quenching, sterilizing, aging, baking, brazing and soldiering, preheating, curing, drying, foundry etc.

- Vacuum is used in various ways for cleaning, drying, cooking etc. The technology has advanced so much that tedious if the tasks have become so easy in our daily lives.

- They have also been a boon to the industries and have helped them cater to larger requirements and demands from their clients and orders.

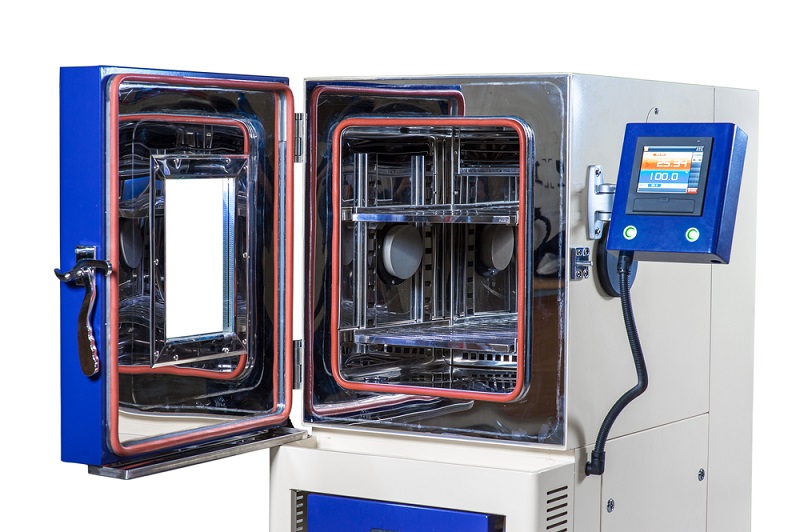

Industrial Ovens: Industries stock a range of ovens for batch processing of substances. The industrial oven models are available where you can heat temperatures up to 750°C. It takes huge volumes as well. It averages up to more than thirteen thousand liters. This will help industries to meet the increasing demands and for different requirements from customers.

Industrial Oven Details

Typical applications of our industrial ovens include:

- drying,

- baking, or

- Curing components.

If there is a specific need for your business, manufacturers can cater to your needs. It is a blessing that high temperature industrial ovens and large general purpose industrial ovens can all be modified at the order stage to included sophisticated control systems and data recording.

Robust vacuum oven demonstrates its strength by showing:

- short warming up times,

- high-precision temperature control

- and turbo-drying,

Additionally it can handle heat-sensitive substances like cosmetics, food, etc. It is very gentle while drying delicate items. The Thermal oven or otherwise called as drying oven in layman terms.

What are thermal drying ovens?

Thermal ovens and drying ovens are used in research and industry in a wide variety of applications. Some examples are listed here:

- It is used in the pharmaceutical industry the food industry etc

- It is used in plastic industry for the ageing of plastics

- It is used in hospitals to warm up blankets, rinsing solutions, etc.

Benefits of vacuum oven drying

- It is great for materials that would be damaged if exposed to high temperatures.

- The vacuum not only removes moisture but also avoids oxidation or explosions that can occur when certain materials combine with air.

- Vacuum drying is also perfect in cases where a solvent is intended to be recovered.

- Also in cases where materials must be dried to very low levels of moisture.

- Saves time as compared to atmospheric drying.

- Saves money as drying at low temperatures causes reduction in energy consumption.

- Employee friendly as the drying happens in closed chambers and hazardous chemical are not release which may cause harm to the people at work.

- Homogenous specific drying. The temperature remains uniform and the drying results are reproducible. There is also another advantage that the light materials are not swirled and protection given to the lab. Moreover, the vacuum oven is less noisier.

What are the things to be aware of, when you operate the vacuum drying oven?

Difficult to handle and maintain as the material exposed to these vacuum ovens must be vacuum compatible.

In the food industry the natural taste is destroyed also the experts say that the nutrition is also destroyed.

Vacuum tubes are large and not easily portable.

There are plenty of documents available on the internet for a research.

A lot of information is available on the internet. A lot of manufacturers and suppliers are out there who provide great service. You can check for reviews and benefits ofvacuum oven and opt for the one that best suits your need.